OPGW Optical Ground Wire

OPGW Optical Ground Wire

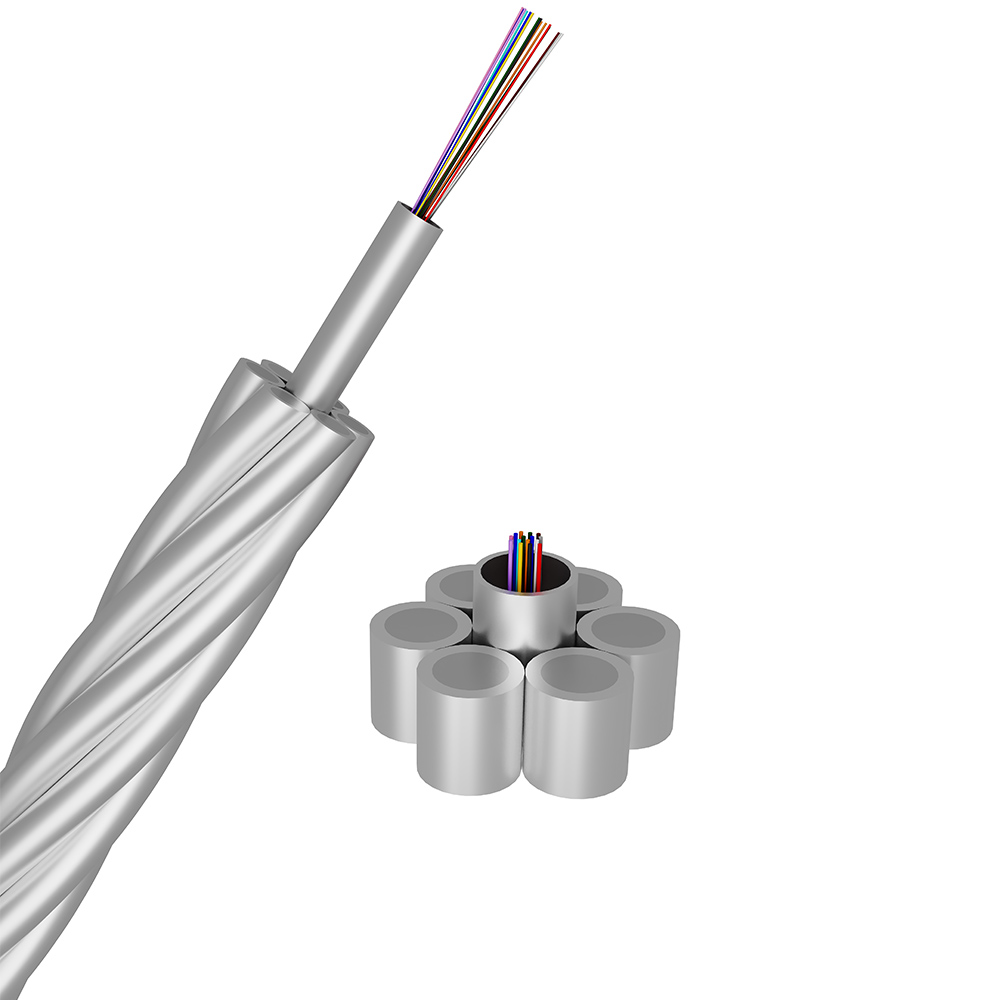

Central Optical Unit Type Optical Unit In The Center Of Cable

Optical ground wire (OPGW) is a dual functioning cable. It is designed to replace traditional static/shield/earth wires on overhead transmission lines with the added benefit of containing optical fibers which can be used for telecommunications purposes. OPGW must be capable of withstanding the mechanical stresses applied to overhead cables by environmental factors such as wind and ice. OPGW must also be capable of handling electrical faults on the transmission line by providing a path to ground without damaging the sensitive optical fibers inside the cable.

The OPGW cable design is constructed of a fiber optic core (with single tube optical fiber unit depending on the fiber count) encased in a hermetically sealed hardened aluminum pipe with a covering of one or more layers of steel and/or alloy wires. Installation is very similar to the process used to install conductors, although care must be taken to use the proper sheave or pulley sizes so as not to cause damage or crush the cable. After installation, when the cable is ready to be spliced, the wires are cut away exposing the central aluminum pipe which can easily be ring-cut with a pipe cutting tool. The color-coded sub-units are preferred by most users because they make splice box preparation very simple.

Product Video

Product Features

Preferred option for easy handling and splicing.

Thick-walled aluminum pipe (stainless steel) provides excellent crush resistance.

Hermetically sealed pipe protects optical fibers.

Outer wire strands selected to optimize mechanical and electrical properties.

Optical sub-unit provides exceptional mechanical and thermal protection for fibers.

Dielectric color-coded optical sub-units are available in fiber counts of 6, 8, 12, 18 and 24.

Multiple sub-units combine to achieve fiber counts up to 144.

Small cable diameter and light weight.

Obtaining appropriate primary fiber excess length within stainless steel tube.

The OPGW has good tensile, impact and crush resistance performance.

Matching with the different ground wire.

Applications

For use by electric utilities on transmission lines in lieu of traditional shield wire.

For retrofit applications where existing shield wire needs to be replaced with OPGW.

For new transmission lines in lieu of traditional shield wire.

Voice, video, data transmission.

SCADA networks.

Cross Section

Specifications

| Model | Fiber Count | Model | Fiber Count |

| OPGW-24B1-40 | 24 | OPGW-48B1-40 | 48 |

| OPGW-24B1-50 | 24 | OPGW-48B1-50 | 48 |

| OPGW-24B1-60 | 24 | OPGW-48B1-60 | 48 |

| OPGW-24B1-70 | 24 | OPGW-48B1-70 | 48 |

| OPGW-24B1-80 | 24 | OPGW-48B1-80 | 48 |

| Other type can be made as customers request. | |||

Packaging And Drum

OPGW shall be wound around a non-returnable wooden drum or iron-wooden drum. Both ends of OPGW shall be securely fastened to drum and sealed with a shrinkable cap. The required marking shall be printed with a weatherproof material on the outsides of drum according to customer's requirement.

If you're looking for a reliable, high-speed fibre optic cable solution, look no further than OYI. Contact us now to see how we can help you stay connected and take your business to the next level.

0755-23179541

0755-23179541  sales@oyii.net

sales@oyii.net.png) 8618926041961

8618926041961