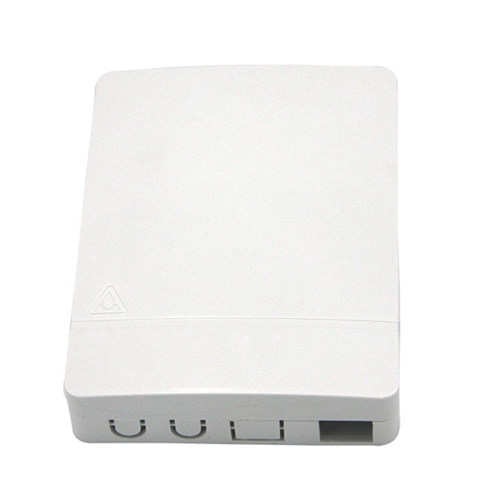

OYI-FOSC HO7

Fiber Optic Splice Closure Horizontal/Inline Type

OYI-FOSC HO7

Product Features

The closure casing is made of high-quality engineering ABS and PP plastics, providing excellent resistance against erosion from acid, alkali salt, and aging. It also has a smooth appearance and a reliable mechanical structure.

The mechanical structure is reliable and can withstand harsh environments, intense climate changes, and demanding working conditions. It has a protection grade of IP68.

The splice trays inside the closure are turn-able like booklets and have sufficient curvature radius and space for winding optical fiber, ensuring a curvature radius of 40mm for optical winding. Each optical cable and fiber can be operated individually.

The closure is compact, has a large capacity, and is easy to maintain. The elastic rubber seal rings inside the closure provide good sealing and sweat-proof performance.

Technical Specifications

|

Item No. |

OYI-FOSC-02H |

|

Size (mm) |

210*210*58 |

|

Weight (kg) |

0.7 |

|

Cable Diameter (mm) |

φ 20mm |

|

Cable Ports |

2 in, 2 out |

|

Max Capacity Of Fiber |

24 |

|

Max Capacity Of Splice Tray |

24 |

|

Sealing Structure |

Silicon Gum Material |

|

Life Span |

More Than 25 Years |

Applications

Telecommunications, railway, fiber repair, CATV, CCTV, LAN, FTTX

Using in communication cable line overhead mounted, underground, direct-buried, and so on.

Packaging Information

Quantity: 20pcs/Outer box.

Carton Size: 50*33*46cm.

N.Weight: 18kg/Outer Carton.

G.Weight: 19kg/Outer Carton.

OEM service available for mass quantity, can print logo on cartons.

Inner Box

Outer Carton

If you're looking for a reliable, high-speed fibre optic cable solution, look no further than OYI. Contact us now to see how we can help you stay connected and take your business to the next level.

0755-23179541

0755-23179541  sales@oyii.net

sales@oyii.net.png) 8618926041961

8618926041961