GYFC8Y53

Self-Supporting Optic Cable

GYFC8Y53

Product Description

The GYFC8Y53 is a high-performance loose tube fiber optic cable engineered for demanding telecommunication applications. Constructed with multi-loose tubes filled with water-blocking compound and stranded around a strength member, this cable ensures excellent mechanical protection and environmental stability. It features multiple single-mode or multimode optical fibers, providing reliable high-speed data transmission with minimal signal loss.

With a rugged outer sheath resistant to UV, abrasion, and chemicals, GYFC8Y53 is suitable for outdoor installations, including aerial use. The cable's flame-retardant properties enhance safety in enclosed spaces. Its compact design allows for easy routing and installation, reducing deployment time and costs. Ideal for long-haul networks, access networks, and data center interconnections, GYFC8Y53 offers consistent performance and durability, meeting international standards for optical fiber communication.

Product Features

1. CABLE CONSTRUCTION

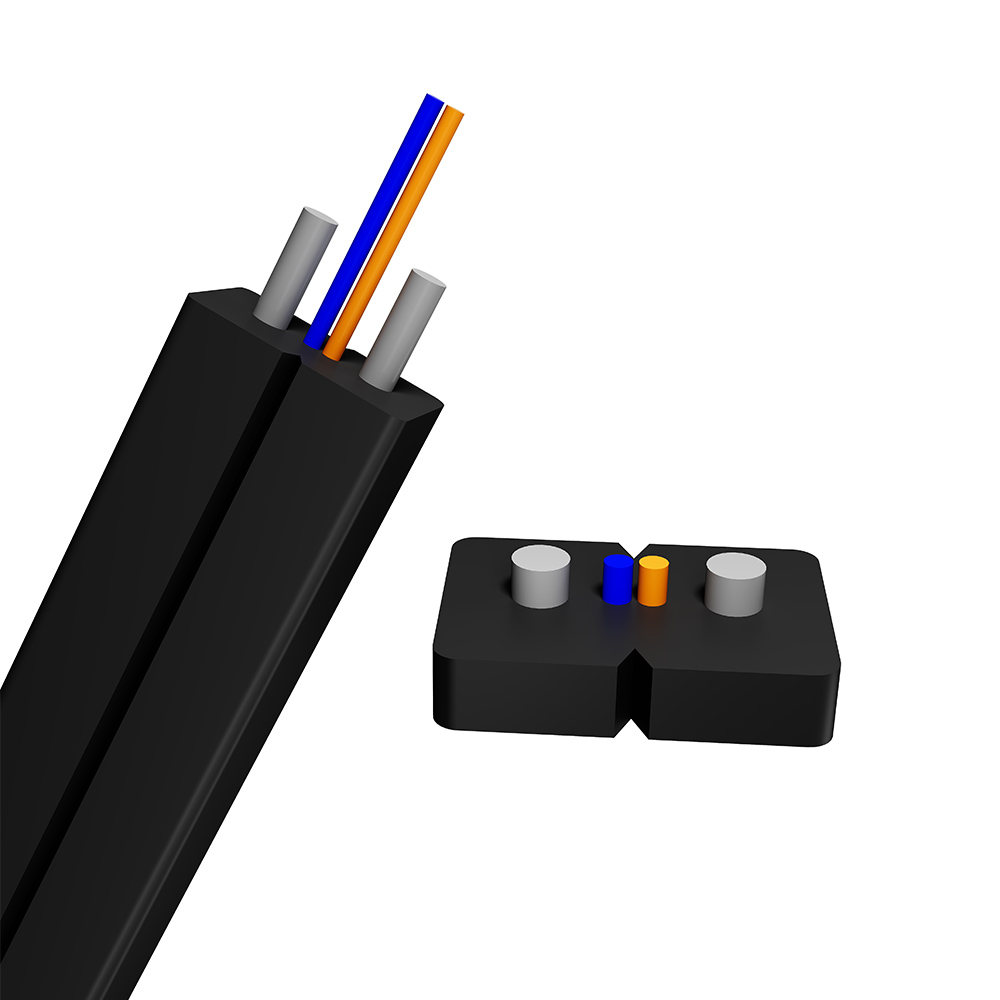

1.1 CROSS SECTIONAL DIAGRAM

1.2 TECHNICAL SPECIFICATION

|

Fiber count |

2~24 |

48 |

72 |

96 |

144 |

||

|

Loose Tube |

OD (mm): |

1.9±0.1 |

2.4±0.1 |

2.4±0.1 |

2.4±0.1 |

2.4±0.1 |

|

|

Material: |

PBT |

||||||

|

Max fiber count/tube |

6 |

12 |

12 |

12 |

12 |

||

|

Core unit |

4 |

4 |

6 |

8 |

12 |

||

|

FRP/Coating(mm) |

2.0 |

2.0 |

2.6 |

2.6/4.2 |

2.6/7.4 |

||

|

Water Block Material: |

Water blocking Compound |

||||||

|

Supporting wire (mm) |

7*1.6mm |

||||||

|

Sheath |

Thickness: |

Non. 1.8mm |

|||||

|

Material: |

PE |

||||||

|

OD of cable (mm) |

13.4*24.4 |

15.0*26.0 |

15.4*26.4 |

16.8*27.8 |

20.2*31.2 |

||

|

Net weight (kg/km) |

270 |

320 |

350 |

390 |

420 |

||

|

Operating temperature range(°C) |

-40~+70 |

||||||

|

Tensile strength short/ long term(N) |

8000/2700 |

||||||

2.FIBER AND LOOSE BUFFER TUBE IDENTIFICATION

|

NO. |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

Tube Color |

Blue |

Orange |

Green |

Brown |

Slate |

White |

Red |

Black |

Yellow |

Violet |

Pink |

Aqua |

|

NO. |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

Fiber Color |

Blue |

Orange |

Green |

Brown |

Slate |

natural |

Red |

Black |

Yellow |

Violet |

Pink |

Aqua |

3. OPTICAL FIBER

3.1 Single Mode Fiber

|

ITEMS |

UNITS |

SPECIFICATION |

||

|

Fiber type |

|

G652D |

G657A |

|

|

Attenuation |

dB/km |

1310 nm≤ 0.35 1550 nm≤ 0.21 |

||

|

Chromatic Dispersion |

ps/nm.km |

1310 nm≤ 3.5 1550 nm≤18 1625 nm≤ 22 |

||

|

Zero Dispersion Slope |

ps/nm2.km |

≤ 0.092 |

||

|

Zero Dispersion Wavelength |

nm |

1300 ~ 1324 |

||

|

Cut-off Wavelength (lcc) |

nm |

≤ 1260 |

||

|

Attenuation vs. Bending (60mm x100turns) |

dB |

(30 mm radius,100 rings ) ≤ 0.1 @ 1625 nm |

(10 mm radius,1 ring)≤ 1.5 @ 1625 nm |

|

|

Mode Field Diameter |

mm |

9.2 ± 0.4 at 1310 nm |

9.2 ± 0.4 at 1310 nm |

|

|

Core-Clad Concentricity |

mm |

≤ 0.5 |

≤ 0.5 |

|

|

Cladding Diameter |

mm |

125 ± 1 |

125 ± 1 |

|

|

Cladding Non circularity |

% |

≤ 0.8 |

≤ 0.8 |

|

|

Coating Diameter |

mm |

245 ± 5 |

245 ± 5 |

|

|

Proof Test |

Gpa |

≥ 0.69 |

≥ 0.69 |

|

4. Mechanical and Environmental Performance of the Cable

|

NO. |

ITEMS |

TEST METHOD |

ACCEPTANCE CRITERIA |

|

1 |

Tensile Loading Test |

#Test method: IEC 60794-1-E1 -. Long-tensile load: 2700 N -. Short-tensile load:8000 N -. Cable length: ≥ 50 m |

-. Attenuation increment@1550 nm: ≤ 0.1 dB -. No jacket cracking and fiber breakage |

|

2 |

Crush Resistance Test |

#Test method: IEC 60794-1-E3 -. Long load: 1000 N/100mm -. Short-load: 2200 N/100mm Load time: 1 minutes |

-. Attenuation increment@1550 nm: ≤ 0.1 dB -. No jacket cracking and fiber breakage |

|

3 |

Impact Resistance Test |

#Test method: IEC 60794-1-E4 -. Impact-height: 1 m -. Impact-weigh: 450 g -. Impact-point: ≥ 5 -. Impact-frequency: ≥ 3/point |

-. Attenuation increment@1550 nm: ≤ 0.1 dB -. No jacket cracking and fiber breakage |

|

4 |

Repeated Bending |

#Test method: IEC 60794-1-E6 -. Mandrel-diameter: 20 D (D = cable diameter) -. Subject weight: 15 kg -. Bending-frequency: 30 times -. Bending-speed: 2 s/time |

-. Attenuation increment@1550 nm: ≤ 0.1 dB -. No jacket cracking and fiber breakage |

|

5 |

Torsion Test |

#Test method: IEC 60794-1-E7 -. Length: 1 m -. Subject-weight:15 kg -. Angle: ±180 degree -. Frequency: ≥ 10/point |

-. Attenuation increment@1550 nm: ≤ 0.1 dB -. No jacket cracking and fiber breakage |

|

6 |

Water Penetration Test |

#Test method: IEC 60794-1-F5B -. Height of pressure head: 1 m -. Length of specimen: 3 m -. Test time: 24 hours |

-. No leakage through the open cable end |

|

7 |

Temperature Cycling Test |

#Test method: IEC 60794-1-F1 -. Temperature steps: + 20℃,40℃, + 70℃, + 20℃ -. Testing Time: 24 hours/step -. Cycle-index: 2 |

-. Attenuation increment@1550 nm: ≤ 0.1 dB -. No jacket cracking and fiber breakage |

|

8 |

Drop Performance |

#Test method: IEC 60794-1-E14 -. Testing length: 30 cm -. Temperature range: 70 ± 2℃ -. Testing-Time: 24 hours |

-. No filling compound drop-out |

|

9 |

Temperature |

Operating: -40℃~+60℃ Store/Transport: -50℃~+70℃ Installation: -20℃~+60℃ |

|

5. FIBER OPTIC CABLE BENDING RADIUS

Static bending: ≥ 10 times than cable out diameter.

Dynamic bending: ≥ 20 times than cable out diameter.

6. PACKAGE AND MARK

6.1 PACKAGE

Not allowed two length units of cable in one drum, two ends should be sealed, two ends should be packed inside drum, reserve length of cable not less than 3 meters.

6.2 MARK

Cable Mark: Brand, Cable type, Fiber type and counts, Year of manufacture, Length marking.

7. TEST REPORT

Test report and certification supplied on request.

If you're looking for a reliable, high-speed fibre optic cable solution, look no further than OYI. Contact us now to see how we can help you stay connected and take your business to the next level.

0755-23179541

0755-23179541  sales@oyii.net

sales@oyii.net.png) 8618926041961

8618926041961